Simulated Moving Bed chromatography at CARBOGEN AMCIS AG

CMO for SMB chromatography

A few words about the principle of operation of SMB, the secret of its efficiency

Simulated moving bed chromatography principle

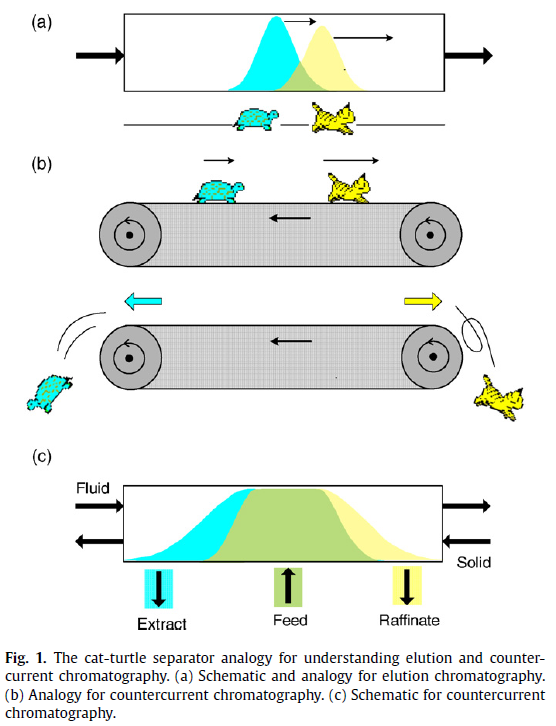

Simulated Moving Bed (SMB) is, in contrast to batch chromatography, a continuous counter current process. The counter current principle can be vividly illustrated using the cat-turtle separator analogy, as described in [A. Rajendran et al., Review: Simulated moving bed chromatography for the separation of enantiomers, Journal of Chromatography A, 1216 (2009) 709-738]. We consider a group of swift cats and sluggish turtles running on a conveyor belt that is moving in their opposite direction at a velocity that is intermediate to that of the two groups of animals. Therefore, the cats have a net velocity to the right, while the turtles to the left. If cats and turtles keep jumping onto the middle part of the belt, they will be conveyed to the two different ends of the belt, i.e. they will be separated in a continuous way (see Fig. 1).

Coming back to chromatography, the equivalent would be a true counter current flow of the fluid and the solid phase (true moving bed (TMB)), where a binary mixture (e.g. enantiomers) is separated continuously. The SMB is a technical approximation of the TMB idea, which can hardly be realized in practice. The SMB is a practical implementation of the TMB concept.

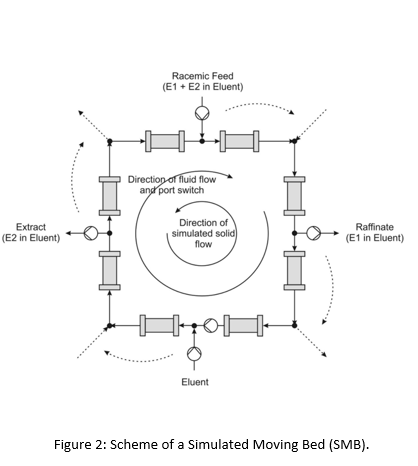

In the SMB process, illustrated in Fig. 2, conventional fixed bed chromatographic columns can be used, and the inlet and outlet ports to the unit are switched periodically in the direction of the fluid flow so as to simulate, in a discontinuous manner, the continuous counter current movement of the solid phase in the TMB process. It is a highly efficient process, since the mixture to be separated can be pumped in continuously and the stationary phase in the columns is constantly loaded to a very high degree. Compared to a binary separation by batch chromatography, the SMB process is by far superior in terms of solvent consumption and productivity.

CARBOGEN AMCIS AG offers a vast range of in-house & tailored chromatography solutions from lab to commercial scale.

Dedicated chromatography experts with more than 20 years of experience in industrial chromatography are committed to helping customers during Active Pharmaceutical Ingredients (API) development. Together with experts from development, analytics and production, they work in a team to develop an efficient separation process for the customer. The SMB separation step may be a fully integrated part of the synthesis or a stand-alone process including the isolation of the enantiomers.

SMB chromatography is a binary separation technology, where the chromatogram is "cut into two pieces". Thus, it is ideally suited for enantiomer separations like racemic or enantiomerically enriched mixtures. In addition, SMB is also suited for separation of diastereomers or separation of impurity and main component or any pseudo-binary separation.

At CARBOGEN AMCIS AG, Simulated Moving Bed technology is a proven separation method and frequently used to successfully introducing enantiomeric purity in the synthetic pathway towards the final API. The well-established advantages from the very efficient continuous, countercurrent SMB operation principle over batch chromatography are higher productivity, lower solvent consumption and better resin usage. SMB is often preferred over chemical or enzymatic chiral synthesis in particular in early phase clinical stages. With moderate development effort, this technology enables processes with high enantiomeric purity and, in parallel, high yield even in the highly regulated environment of the pharmaceutical industry. This makes SMB a time- and cost-efficient tool for the pharmaceutical industry.

Chromatographic purification especially, but not only, in preclinical and early phase development has many advantages:

- The method development for SMB separation is straightforward and fast. The completion of a Screening and Feasibility Study takes approx. 4-5 weeks. This reduces the cycle time and cost for development.

- SMB method development is reliable and delivers a separation method suitable for the planned project.

With the developed SMB method a SMB separation on scale can be started quickly.

SMB equipment available at CGAM

CMO for SMB chromatography

At CARBOGEN AMCIS AG, two SMB plants are available at the Aarau site. These plants are equipped with 6-8 SMB columns with 4.8 cm ID and an average length of 10 cm. The SMB columns are packed with bulk chiral stationary phase (CSP) and tested in house before use. Substances up to category 2 according to the CGAM internal categorization system can be handled (categories 0-4, where 3 and 4 require containment facilities for highly potent compounds).

The advantages of SMB technology

Example for SMB Method Development for an enantiomer separation

The SMB separation method development starts with the determination of the solubility of the racemate in different solvents. A Screening of different chiral stationary phases and eluent systems is performed applying analytical HPLC columns. A suitable combination of chiral stationary phase and eluent system is chosen for further development.

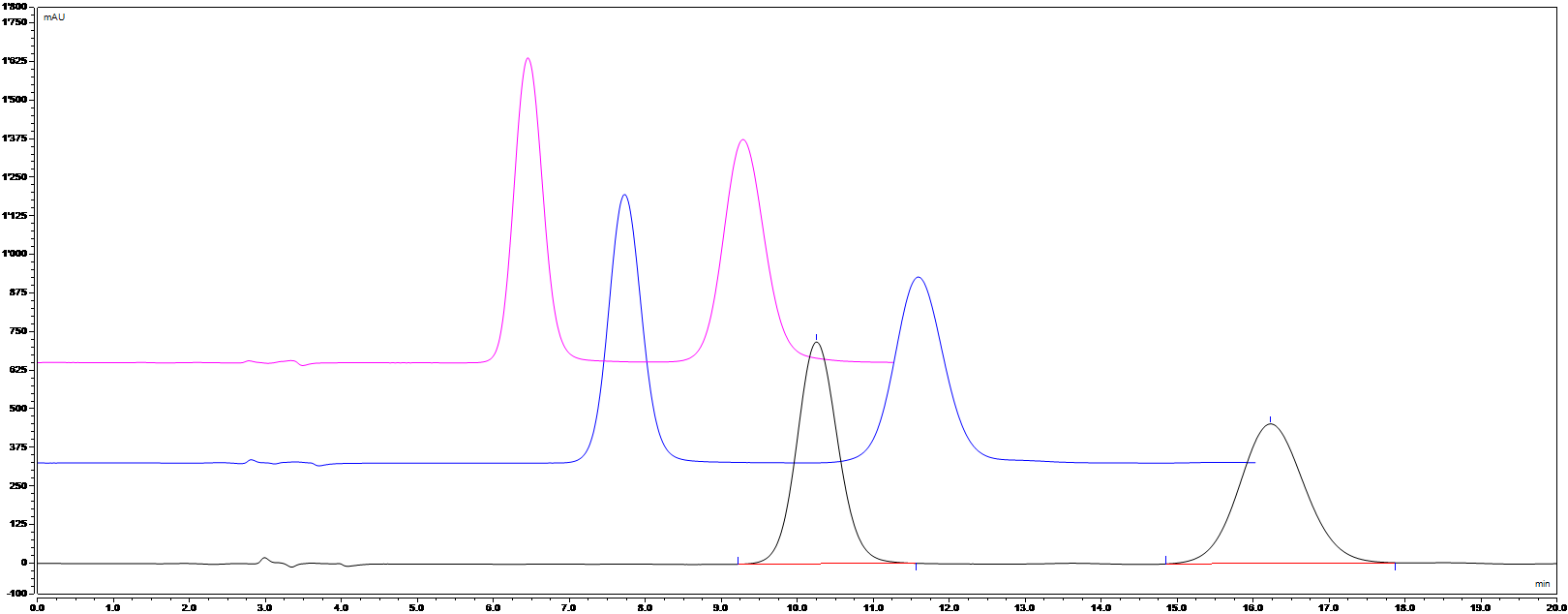

The most promising method resulting from the Screening is further optimized with regard to selectivity and retention time, see Figure 3.

Figure 3: Method optimization

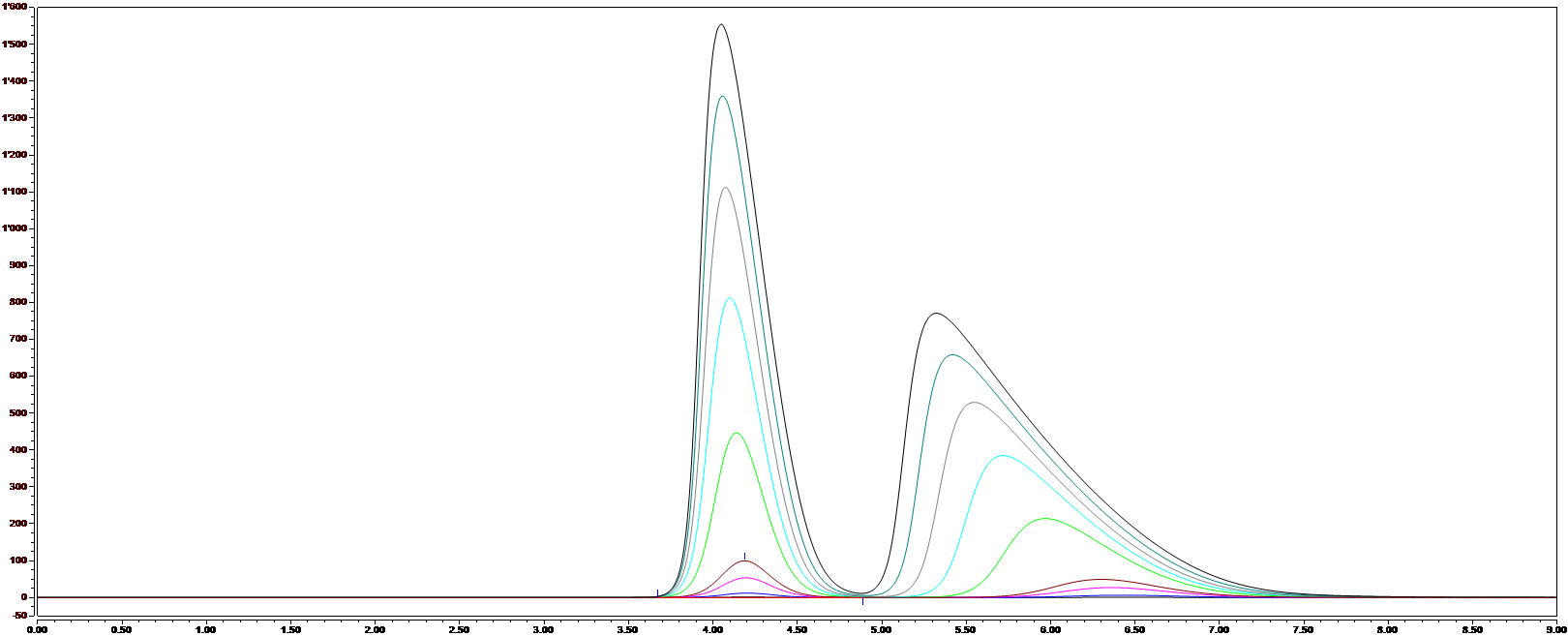

Then, Method Development is continued with the Feasibility Study. Overloaded injections of a concentrated solution of the racemate are performed on an analytical HPLC column, see Figure 4.

Figure 4: Overloaded injections.

The injections are evaluated and SMB performance parameters like productivity are estimated based on software simulations.

In addition, a Stability test of racemate and enantiomers in the chosen eluent system is performed in order to check their stability during SMB processing. For the complete development work ~5 g – 10 g racemate of representative quality is required and ~100 mg target enantiomer for identification of the target.

SMB Separation on Scale

How to scale up SMB chromatography?

In order to start an SMB separation on scale, six to eight SMB columns with heating jacket (10 cm x 4.8 cm ID) are packed and tested for their performance. The eluent is prepared and, for the feed solution, racemate is dissolved in the chosen solvent at a defined concentration. The SMB separation is started with the parameters determined in the Feasibility Study. All optimization is done in the running process. For this purpose samples for In-Process-Controls (IPCs) are taken and analysed for their chiral HPLC purity. Based on the results of the IPCs, the separation parameters are optimized. Once the required chiral purity for the enantiomer streams is reached, the SMB production runs in 24 h operation. Regular IPCs are taken and analysed in order to make sure the required chiral purity is maintained. The fractions of both enantiomers are analysed for their chiral HPLC purity. If this purity fulfils the specification, the corresponding fractions can be worked-up. This could be by evaporation of fractions, precipitation of enantiomer, extraction, or a combination thereof.

Would you like to know more?

Are you interesting to partner with us for a SMB related project?

Elke Huthmann, Senior Chemist Chromatography Services – CARBOGEN ACMIS

Stefanie Abel, Senior Chemist Chromatography Services – CARBOGEN AMCIS